3/2 Mixing Diverting Control Valves

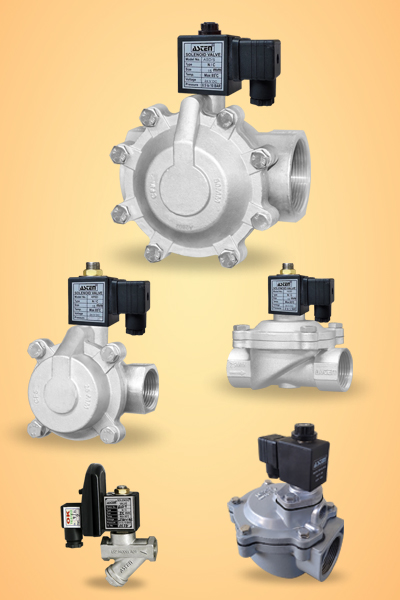

DescriptionA 3/2 mixing diverting control valve is a specific type of control valve used in industrial applications to regulate the flow of fluids, typically liquids or gases. The “3/2” notation refers to the valve’s configuration, which has three ports and two positions. These valves are commonly used in situations where the control of fluid flow direction is required, such as diverting or mixing flows. A 3/2 valve has three ports: an inlet, an outlet, and a common port. The common port is connected to either the inlet or the outlet, depending on the valve’s position.

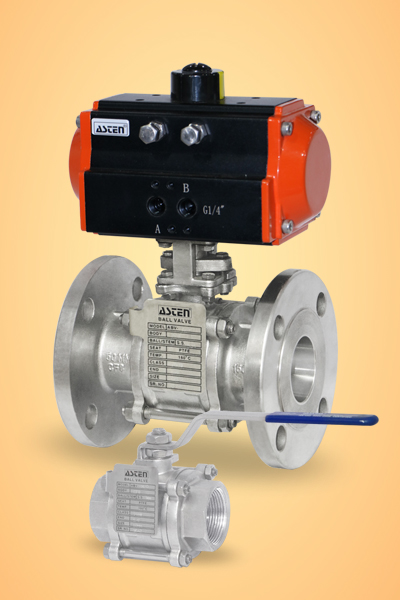

3/2 mixing diverting valves are typically pneumatically actuated. Actuators control the valve’s position based on external signals from a control system.

Applications:

For control of air, water, oil, gas, steam in textile, power generation, paper & pulp, chemical, petro chemical industries, PSA oxygen/nitrogen system, air dryer, gas generator and in process plants.

3/2 mixing diverting control valves are versatile components that offer precise control over fluid flows in various applications. Their ability to switch between mixing and diverting modes makes them valuable for processes that require dynamic control of fluid movement. The choice of actuation type and valve materials should be based on the specific requirements of the application and the characteristics of the fluids being handled.